High Quality

High Efficiency

Precision

Energy Saving

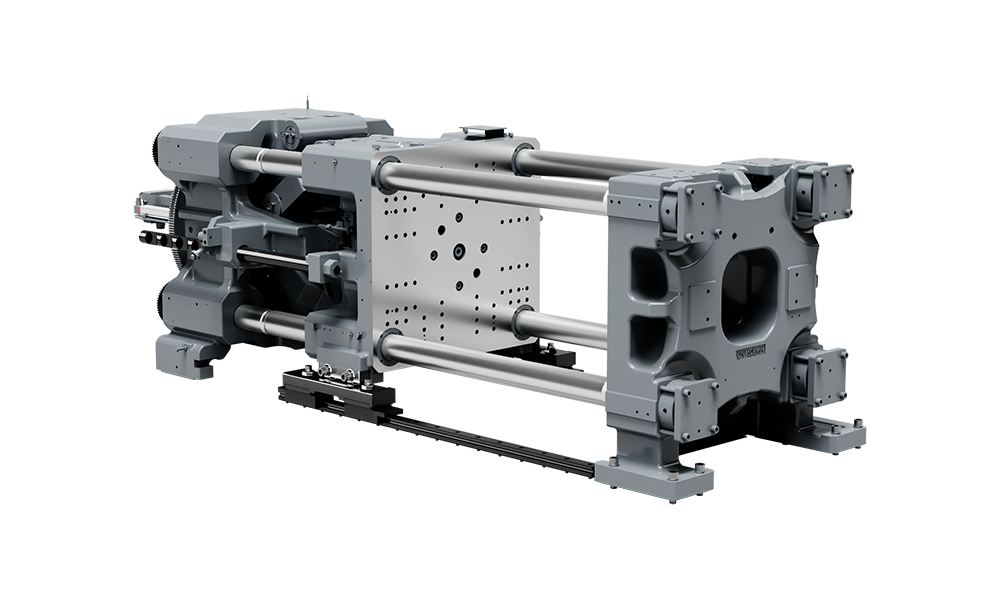

High precision, high strength linear slide rail;

European portable ejection structure design;

All system standard with high rigid template + automatic mold adjustment function;

Mould locking device for high speed and high rigidity cylinder;

Template surface with high rigidity, high flatness and high precision;

Large die stroke and large bulk modulus;

Under the condition of the same tonnage, the inner distance of the tie rod is large;

quantitative centralized lubrication device;

Mechanical and electrical safety devices.

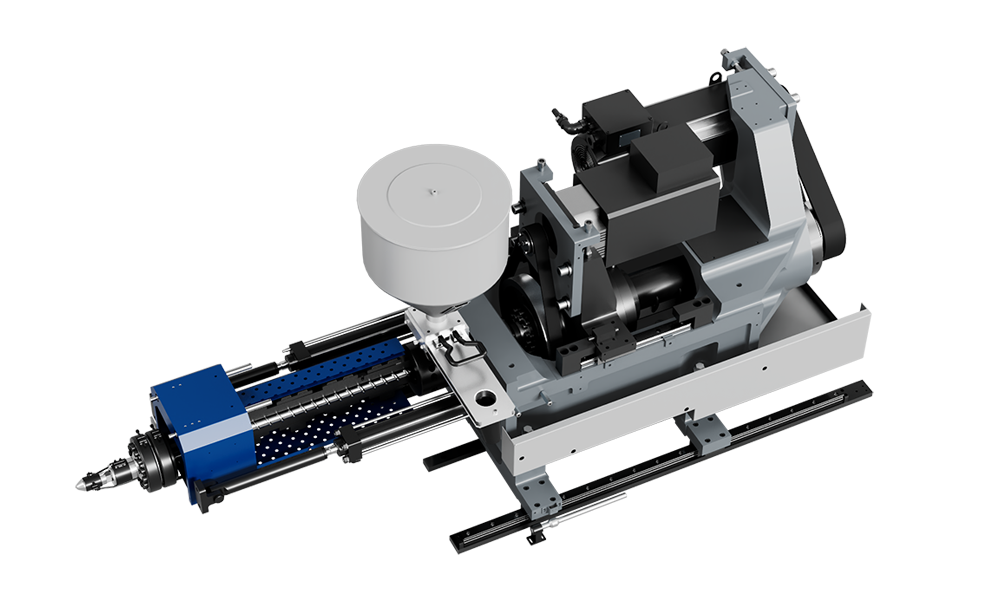

Double screw integrated injection structure;

High rigid shooting platform, high precision sliding rail;

SSR drum temperature control system;

Design of automatic cleaning circuit;

High response ball screw belt drive injection device, fast response, accurate, long service life;

imported high precision ball type special screw;

The plasticizing system independently developed and designed by the Japanese team;

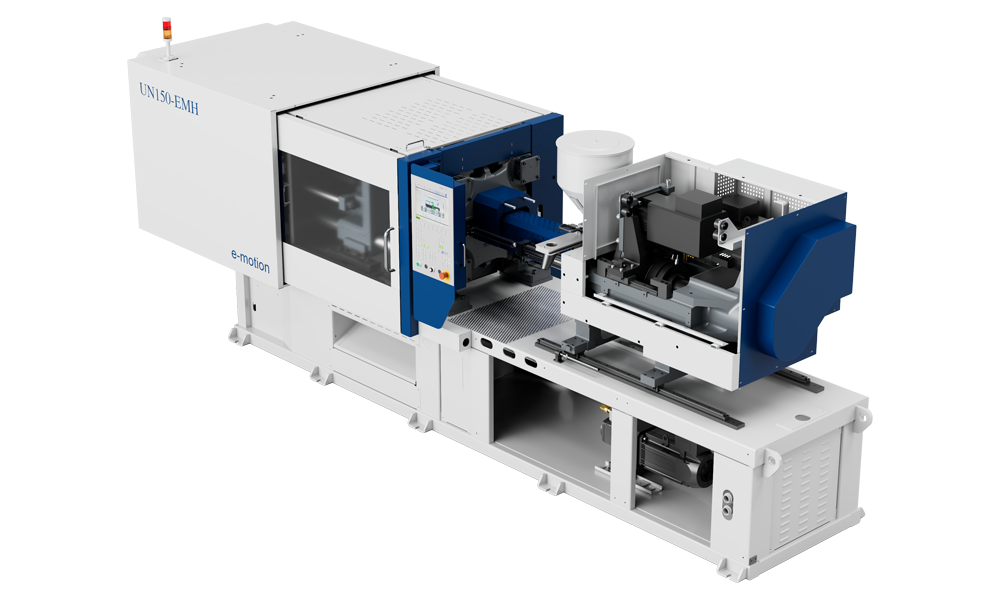

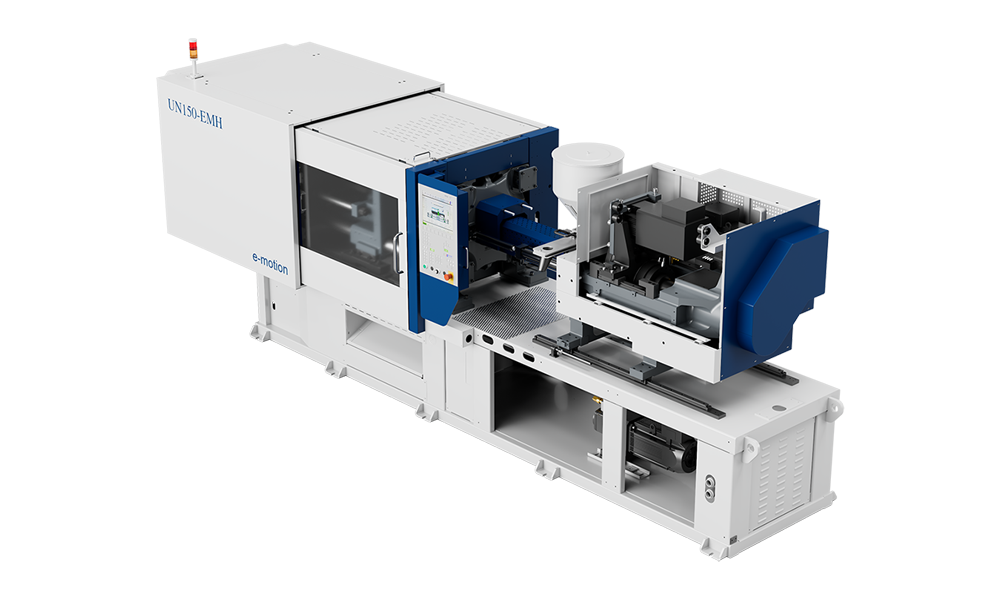

Fully enclosed sheet metal structure, dustproof, anti-noise, beautiful, easy to clean, long service life;

Visualization and graphics of production injection, real-time display of screw speed, position and injection pressure, controllable production process, high efficiency and high precision.

Built-in motor servo hydraulic pump, high speed, high efficiency, energy saving;

Motor with absolute value encoder, position feedback is more reliable, high resolution, high precision of position control;

Injection and melt servo control, injection and melt speed control by servo motor, servo motor response fast, more accurate control, injection position control precision up to 0.01mm;

Standard hydraulic ejection and neutron function, flexible to meet the use of different molds.

Standard KEBA computer 12" Keplast i1180-0110-00 large screen controller, friendly new UI interface, easy to operate, strong performance;

German Industry 4.0 standard to achieve digital and intelligent factory production;

The back pressure of electric melt adhesive is more stable. loadcell sensor is installed to monitor the pressure in the barrel in real time. The injection motor and melt adhesive motor can adjust the pressure in real time according to the feedback pressure, so as to realize the closed-loop control of back pressure.

The lo15adcell sensor is installed to monitor the pressure in the barrel in real time, and the pressure is controlled in a closed-loop manner according to the feedback pressure. The pressure control is more accurate, and the pressure control can be within ±1bar in the stage of pressure holding stability.