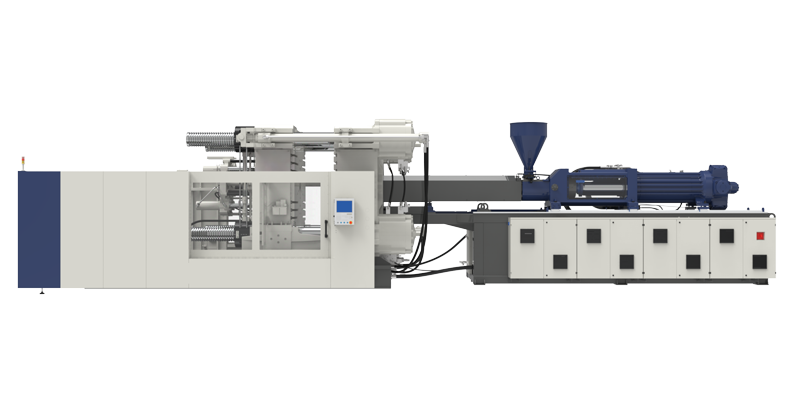

Position accuracy of opening and closing die ±0.2mm, to meet higher requirements for automatic take-up;

Fast response, short scanning time, accurate control, strong digital analysis ability, open a new era of intelligent Internet of Things factory;

injection position accuracy ±0.2mm, product repetition accuracy ≤5;

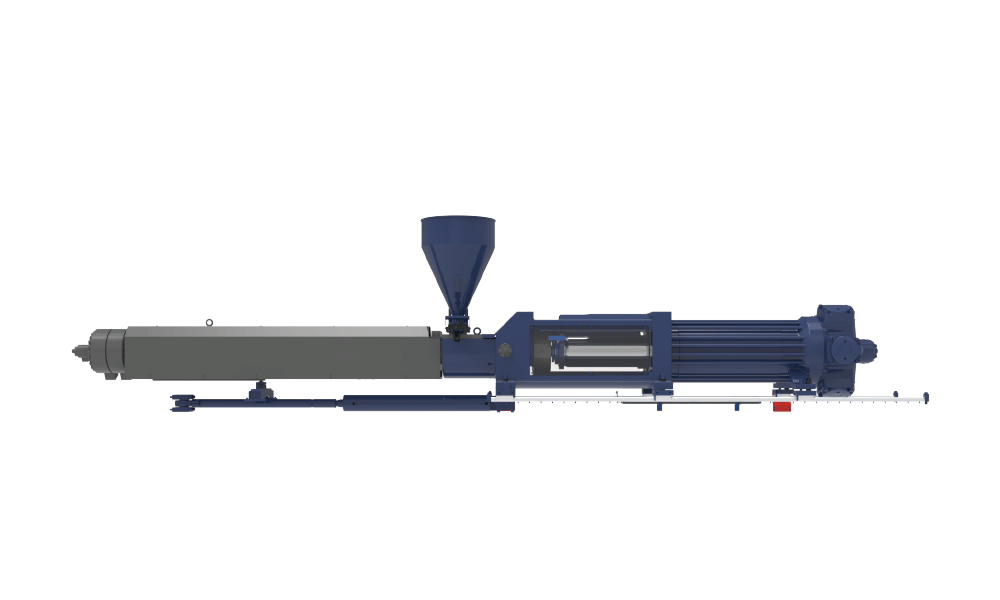

Compared with the three-board machine, the machine covers a small area, effectively improve the plant utilization rate, greatly reduce the investment cost;

Large die opening stroke, die opening and locking stroke is not limited by the structure, can be increased according to the needs of the process;

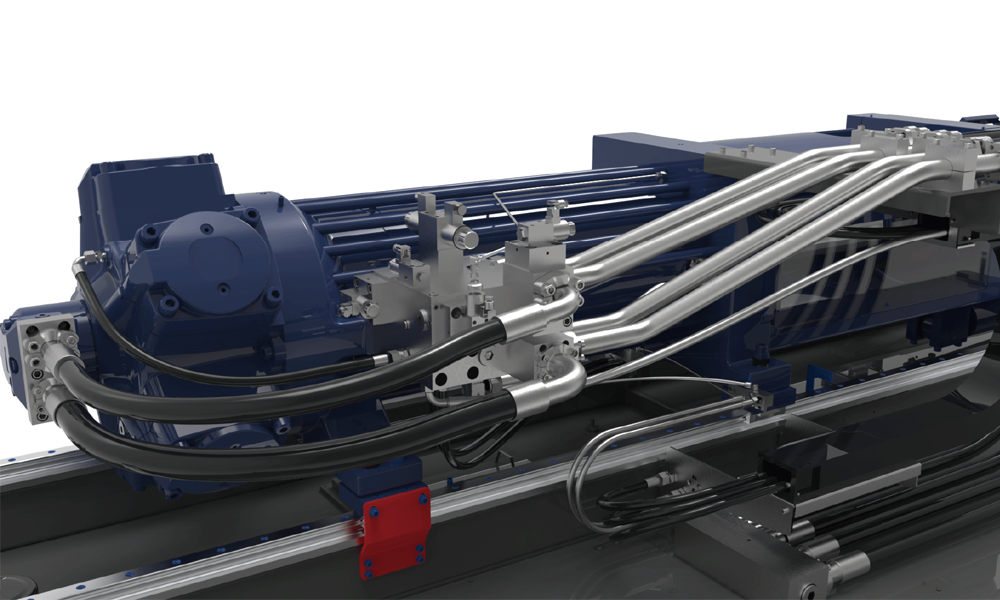

Modular mechanical, hydraulic, electrical design, configuration combination is more flexible and convenient, can meet the personalized needs of customers.

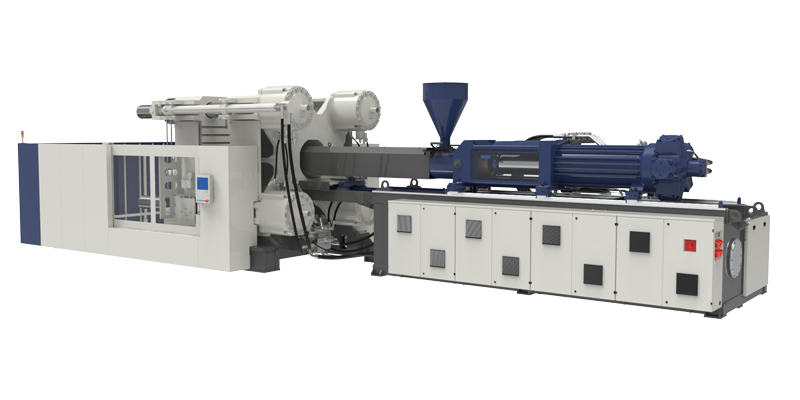

Position accuracy of opening and closing die ±0.2mm, to meet higher requirements for automatic take-up;

Fast response, short scanning time, accurate control, strong digital analysis ability, open a new era of intelligent Internet of Things factory;

injection position accuracy ±0.2mm, product repetition accuracy ≤5;

Compared with the three-board machine, the machine covers a small area, effectively improve the plant utilization rate, greatly reduce the investment cost;

Large die opening stroke, die opening and locking stroke is not limited by the structure, can be increased according to the needs of the process;

Modular mechanical, hydraulic, electrical design, configuration combination is more flexible and convenient, can meet the personalized needs of customers.

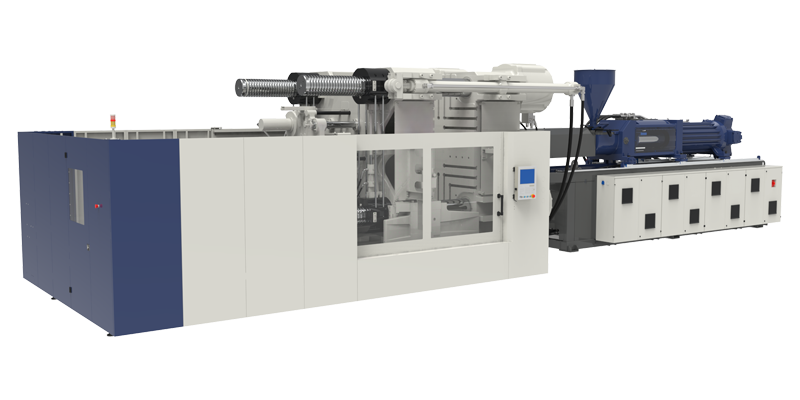

Position accuracy of opening and closing die ±0.2mm, to meet higher requirements for automatic take-up;

Fast response, short scanning time, accurate control, strong digital analysis ability, open a new era of intelligent Internet of Things factory;

injection position accuracy ±0.2mm, product repetition accuracy ≤5;

Compared with the three-board machine, the machine covers a small area, effectively improve the plant utilization rate, greatly reduce the investment cost;

Large die opening stroke, die opening and locking stroke is not limited by the structure, can be increased according to the needs of the process;

Modular mechanical, hydraulic, electrical design, configuration combination is more flexible and convenient, can meet the personalized needs of customers.

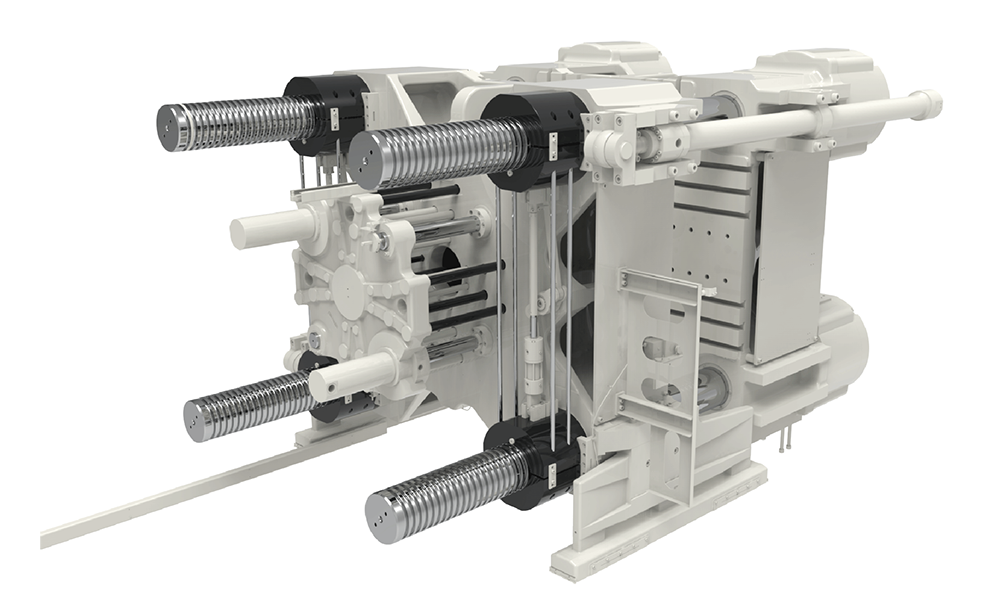

High rigidity and high flatness template: template deformation is small, mold deformation is small, long life, short dry cycle empty cycle, high efficiency and energy saving, high precision products, less flying edge, save material;

Opening and closing mold position precision soil 0.2mm, to meet higher requirements of automatic take-up;

Box-type mold locking fuselage structure design, so that the machine is stable, more stable operation;

T type high rigid linear sliding foot: stable formwork support system, 0.05mm guidance accuracy, to ensure the fast and smooth operation of the template;

Synchronous lock system, lock fast, stable, accurate and reliable;

Short stroke high pressure cylinder design, fast response to pressure construction, more stable and stable mold closing, piston connection using floating structure more reasonable force, oil circuit using European technology - opening and closing mold action control more rapid and stable;

No contact tie rod no friction, low energy consumption, excellent mold protection device, clean and tidy mold area.

Single cylinder injection system, compact structure, low inertia, high injection precision and energy saving;

The use of high rigidity ductile iron, small deformation, more stable injection;

Low friction injection cylinder, fast response, high injection accuracy, high efficiency, more energy saving;

Songtui adopts small oil cavity, small injection resistance, high efficiency, precision and energy saving;

Convenient disassembly can meet customers different injection molding units free combination;

stable feeding port temperature control;

European advanced screw design technology, meet different specifications of screw diameter, wear grade, geometric shape and special mixing requirements, a wide range of application and strong adaptability.

The opening and closing die is more stable and accurate, the die is safer, and the product qualified rate is higher;

Compact space consumption, good cooling effect, constant oil temperature, not affected by the opening and closing mold cycle time and external factors, the machine runs smoothly;

Fast response, long high pressure holding time, more stable opening and closing mold;

Back pressure adopts proportional valve control, higher precision;

DP series two plate injection molding machine, using Austria KEBA two plate machine special control system, strong function, can implement accurate control of pressure, speed, temperature, position, etc., the system is stable, reliable, safe, user-friendly, easy to operate, good application experience.